LFAM for

Defence

|

Why Additive Manufacturing in Defence?

In a sector where reliability and adaptability are paramount, innovation drives progress. With advanced manufacturing solutions, we enable the creation of durable, lightweight, and customized components designed to meet the evolving demands of modern defence.

Rapid Deployment

Accelerate production and deployment timelines to meet urgent operational needs.

Material Innovation

Support advanced studies with precision-built prototypes.

Versatile Manufacturing

Tailor strategies to best match the specific academic and institutional needs.

Complex Customisation

Foster eco-conscious learning with reduced material waste.

Supply Chain Efficiency

Minimise logistical hurdles with streamlined, localized production.

|

Defence Applications

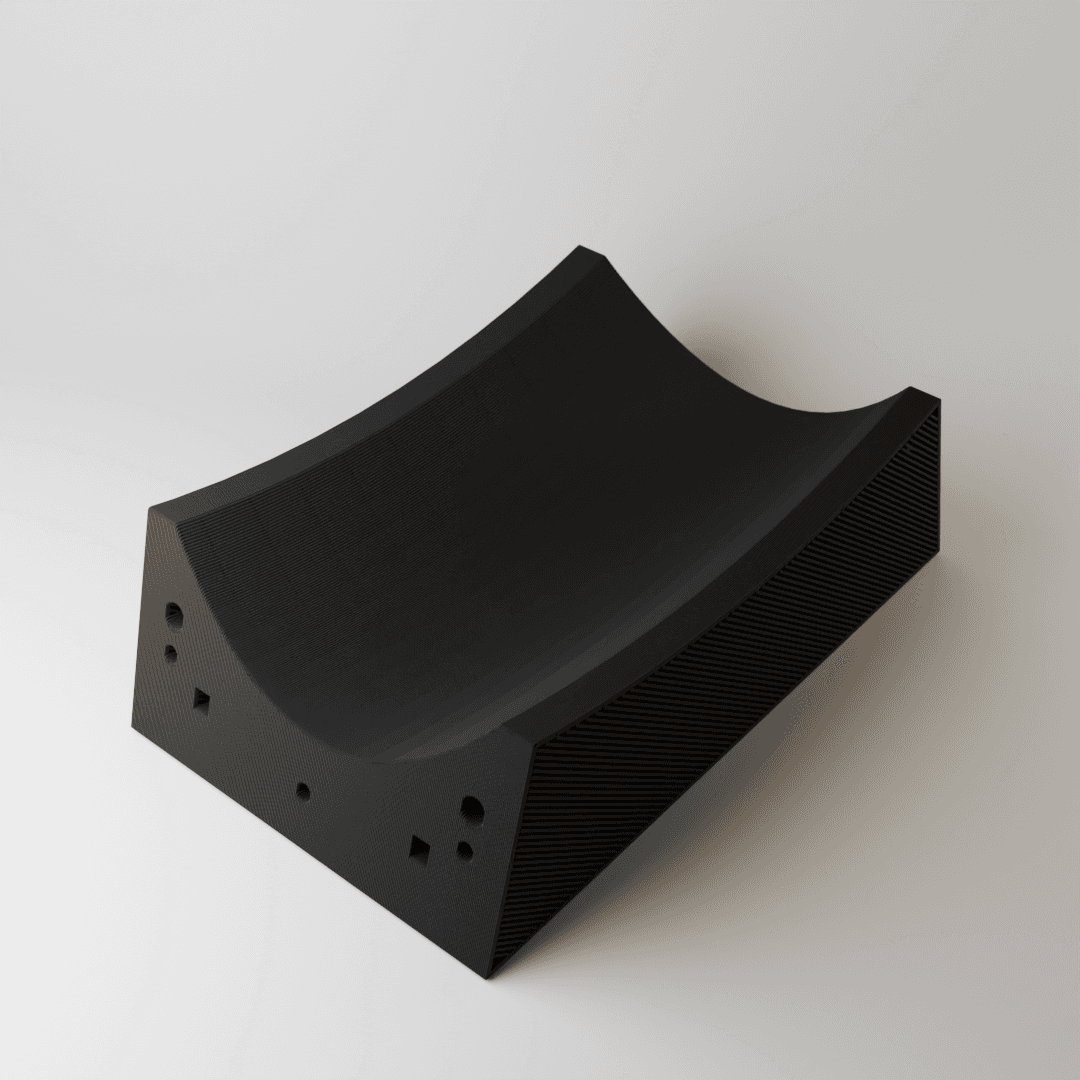

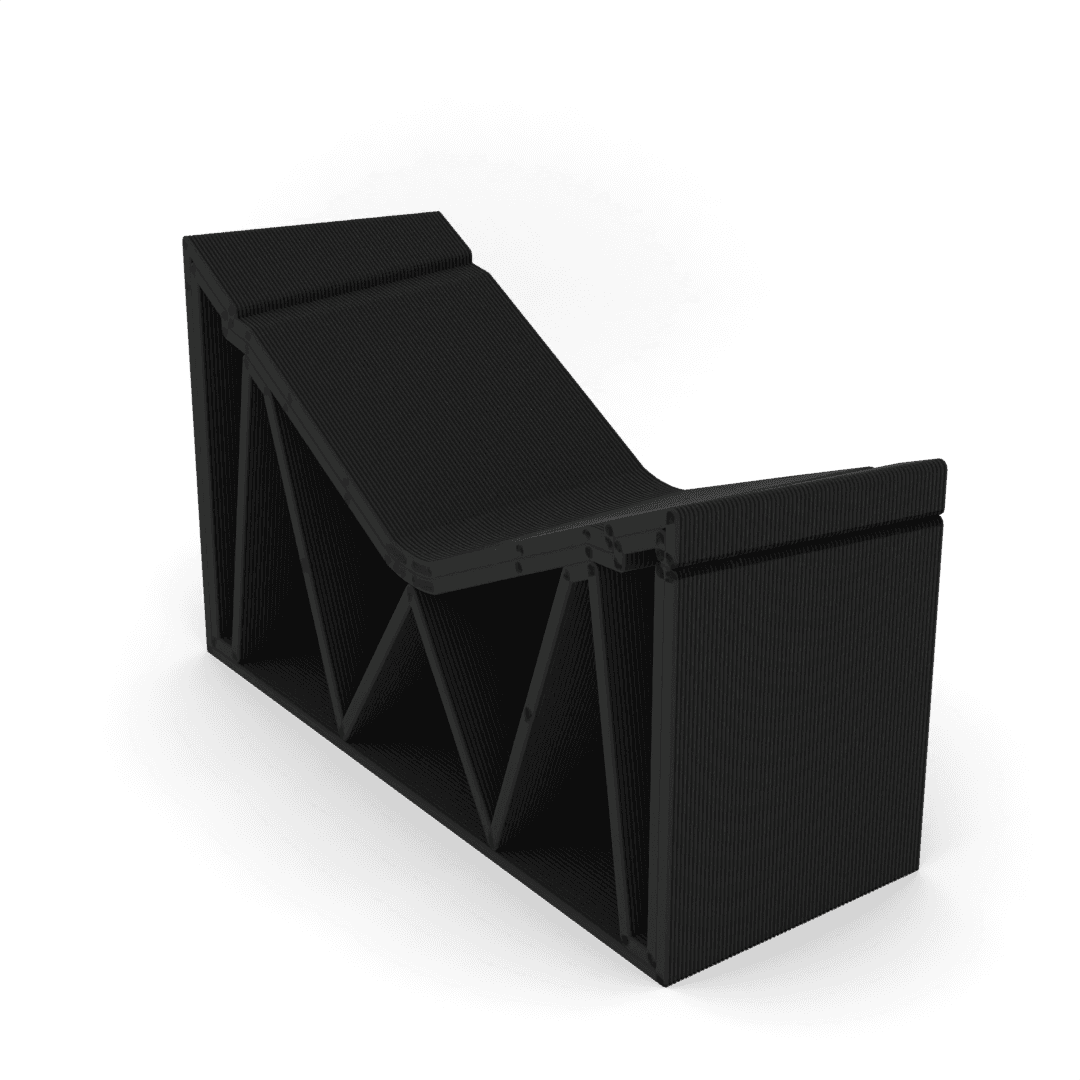

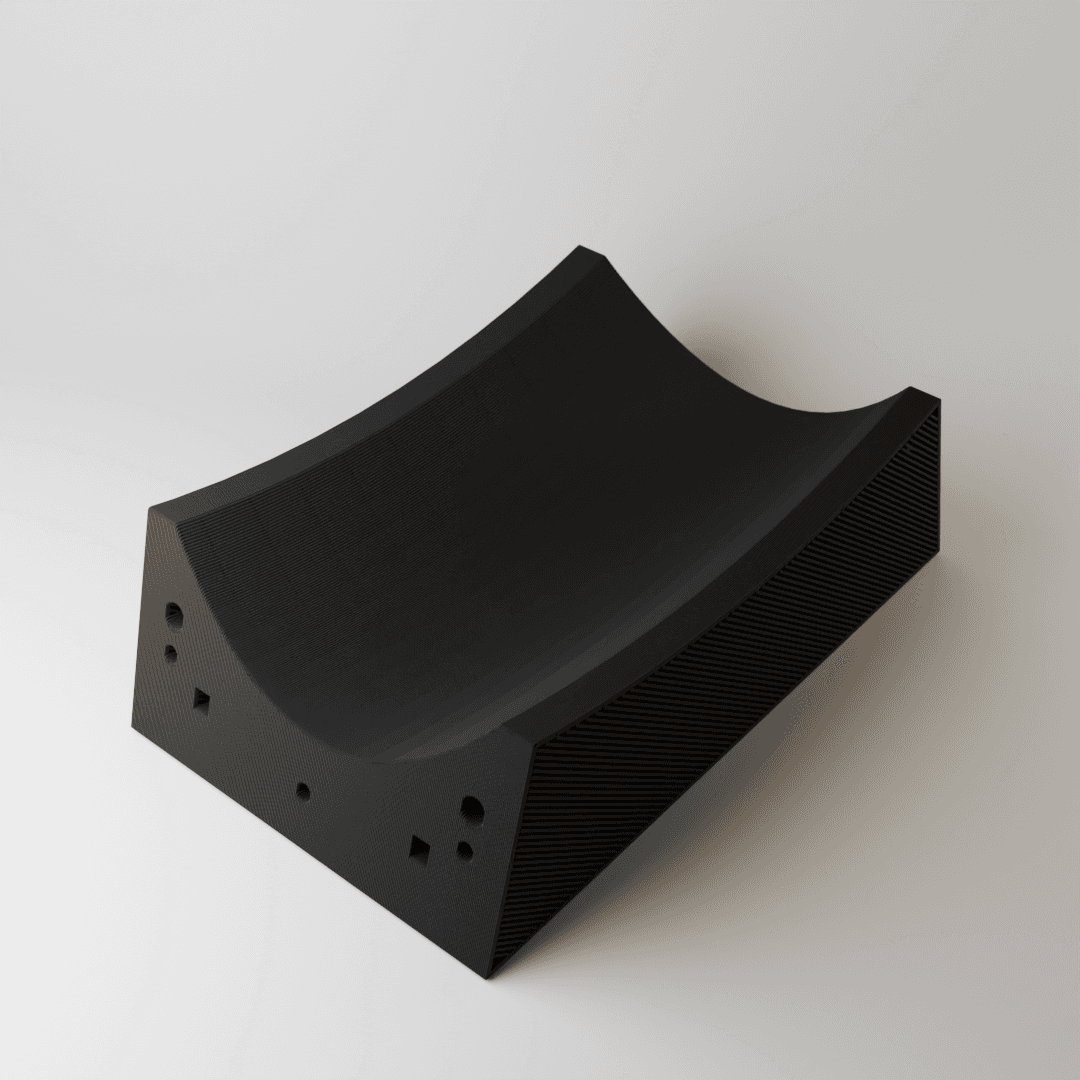

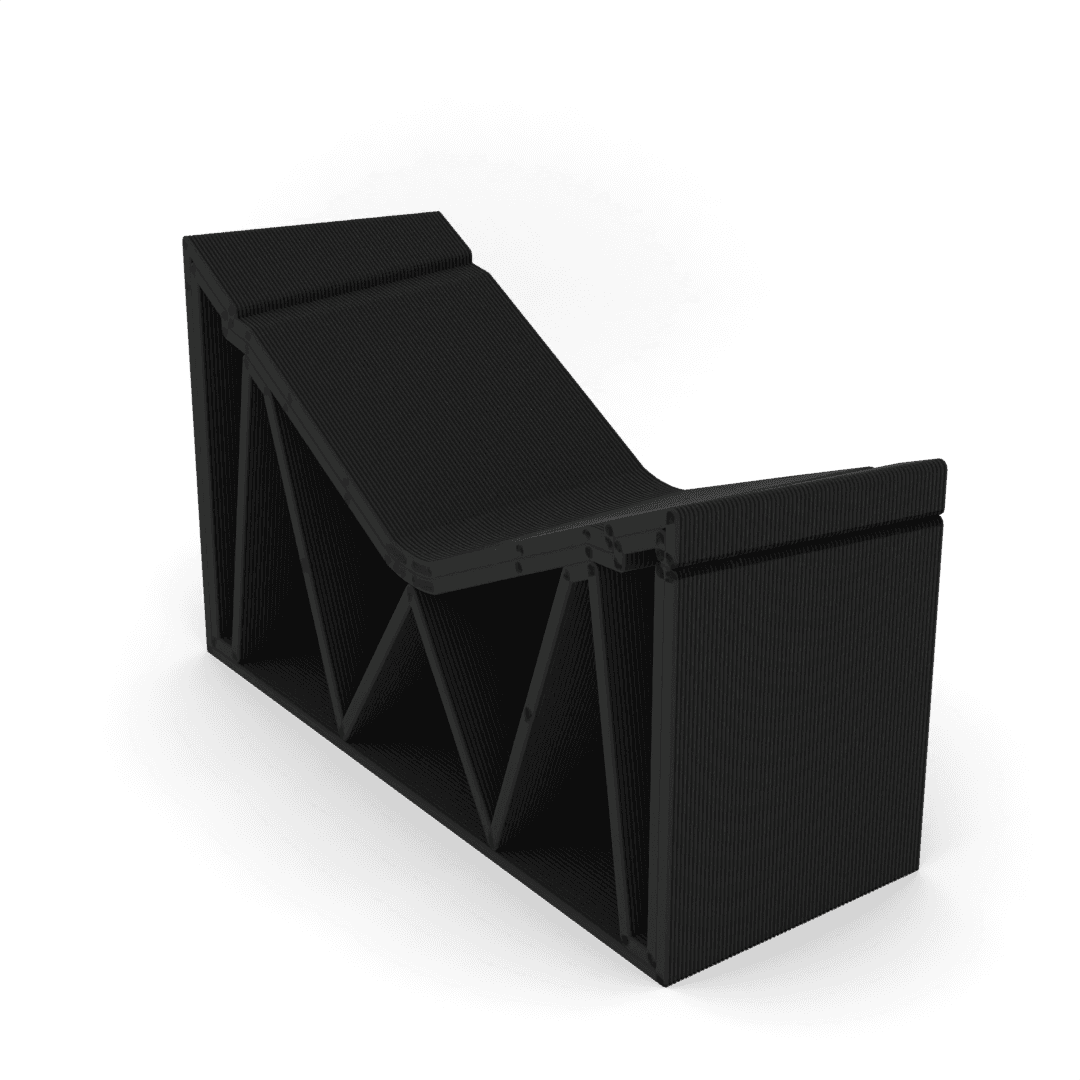

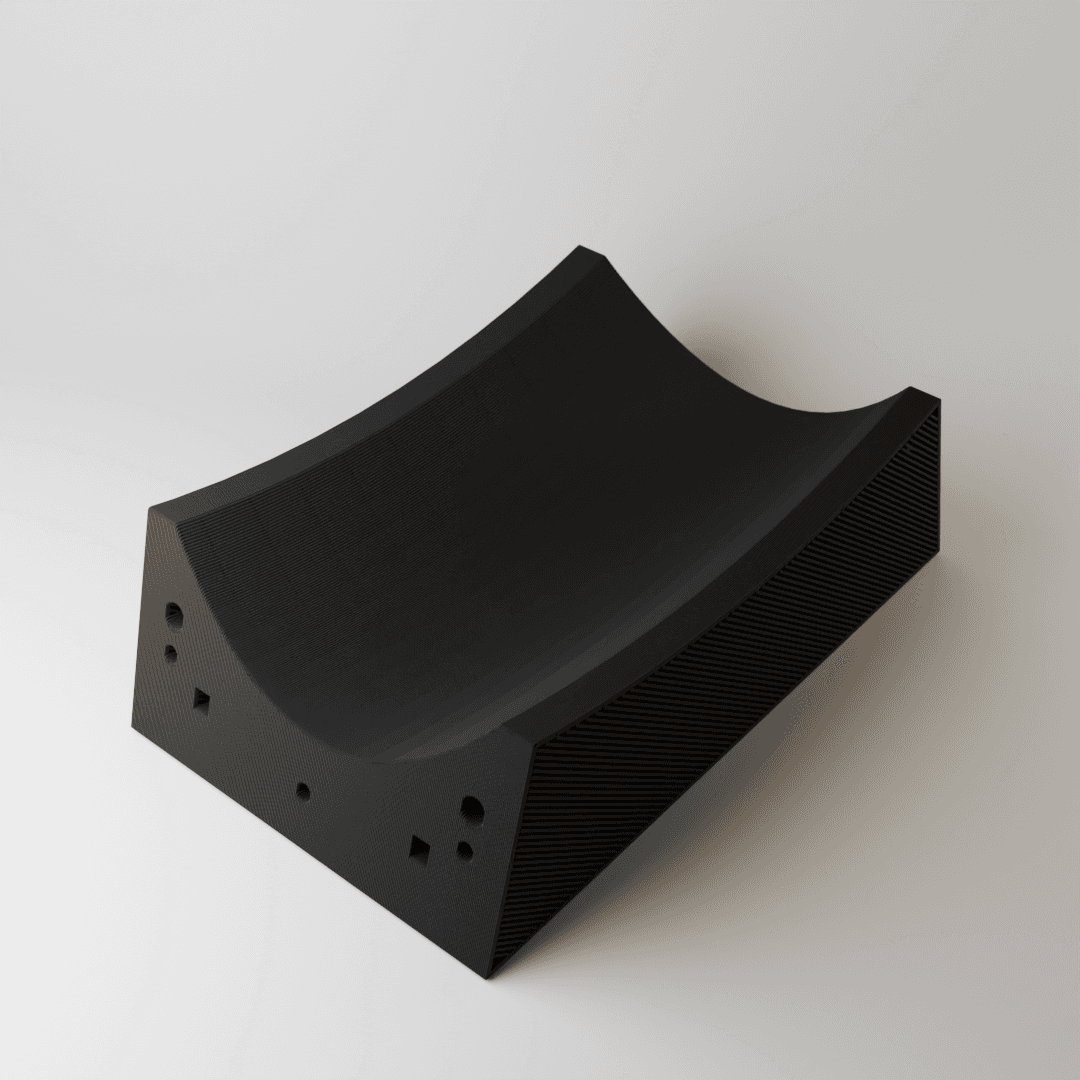

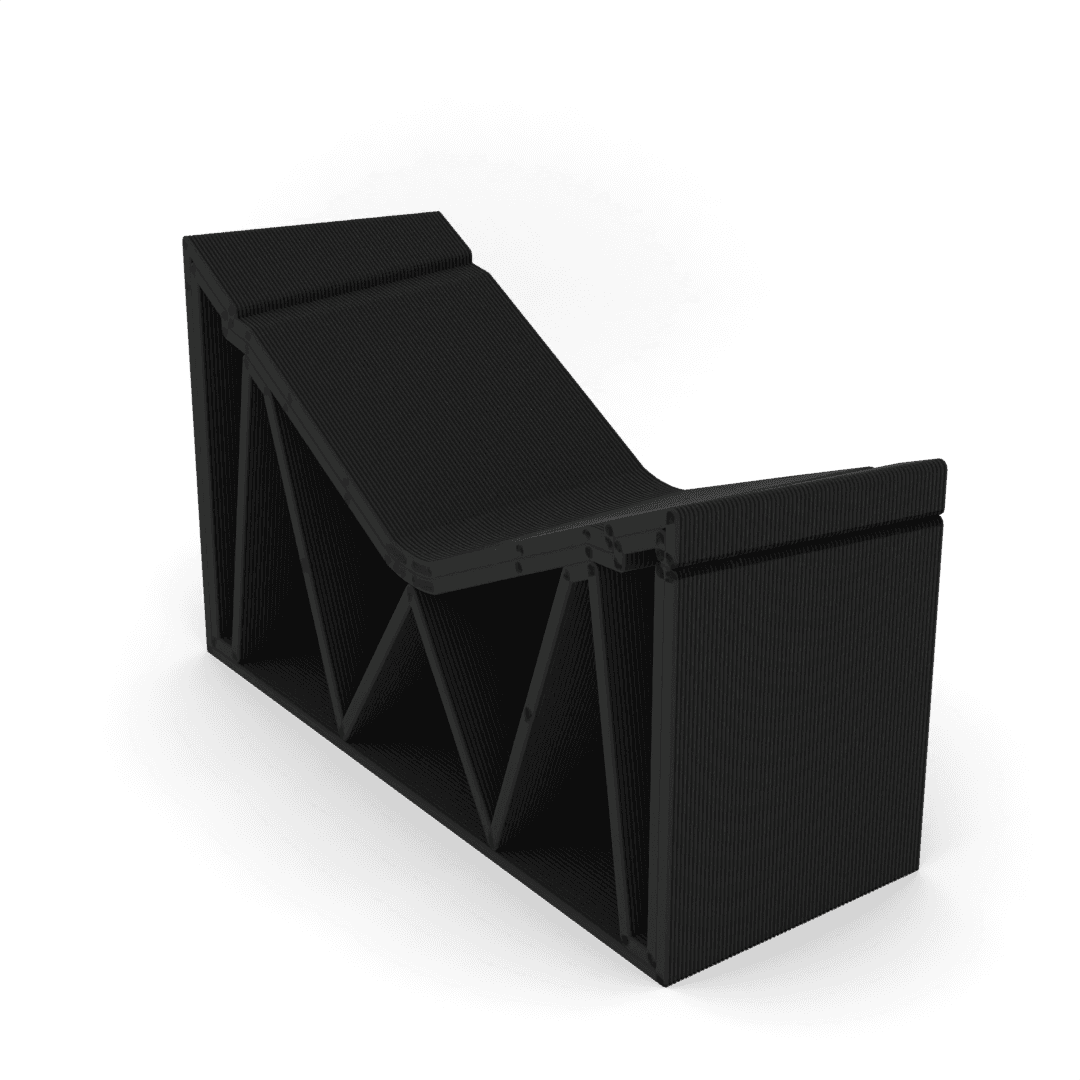

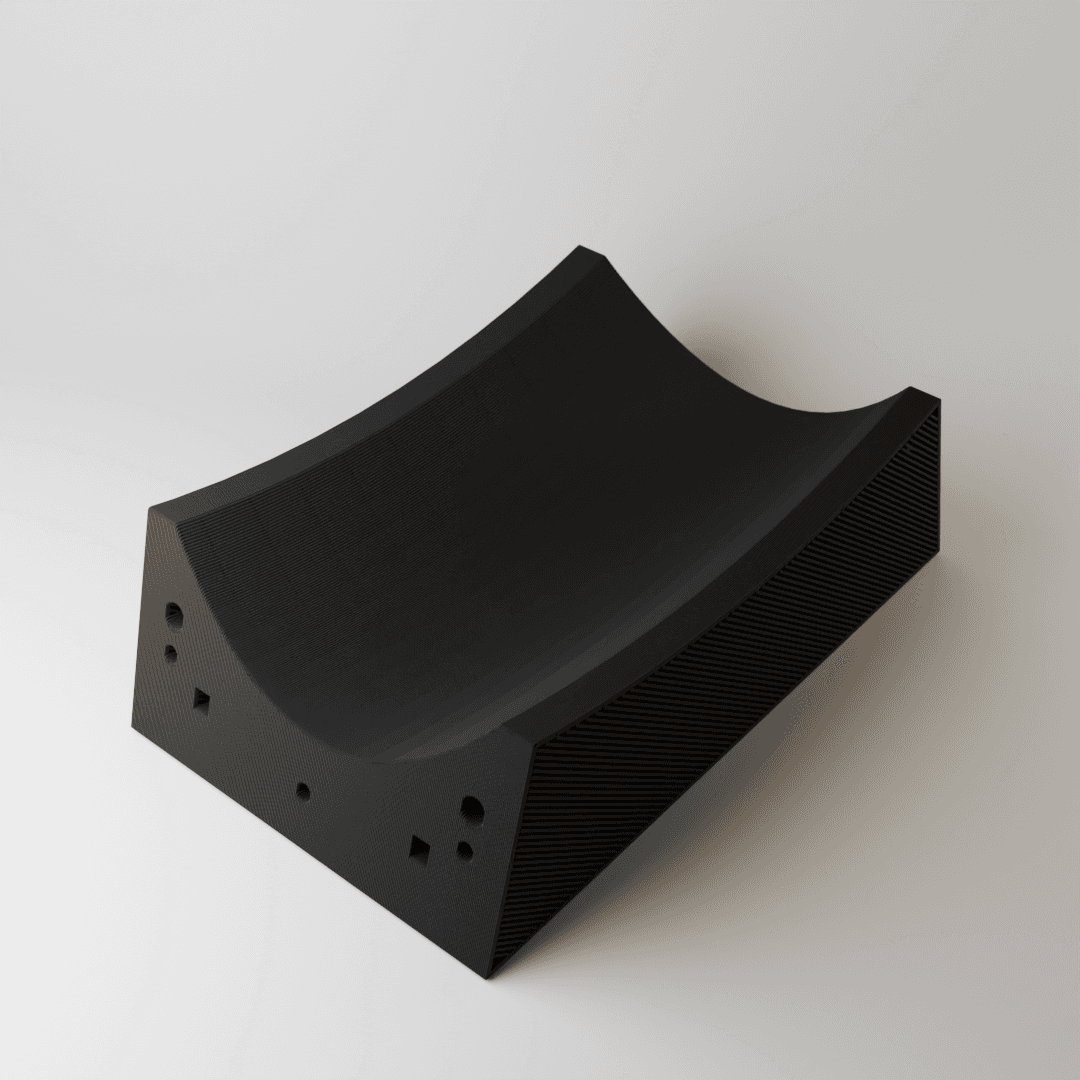

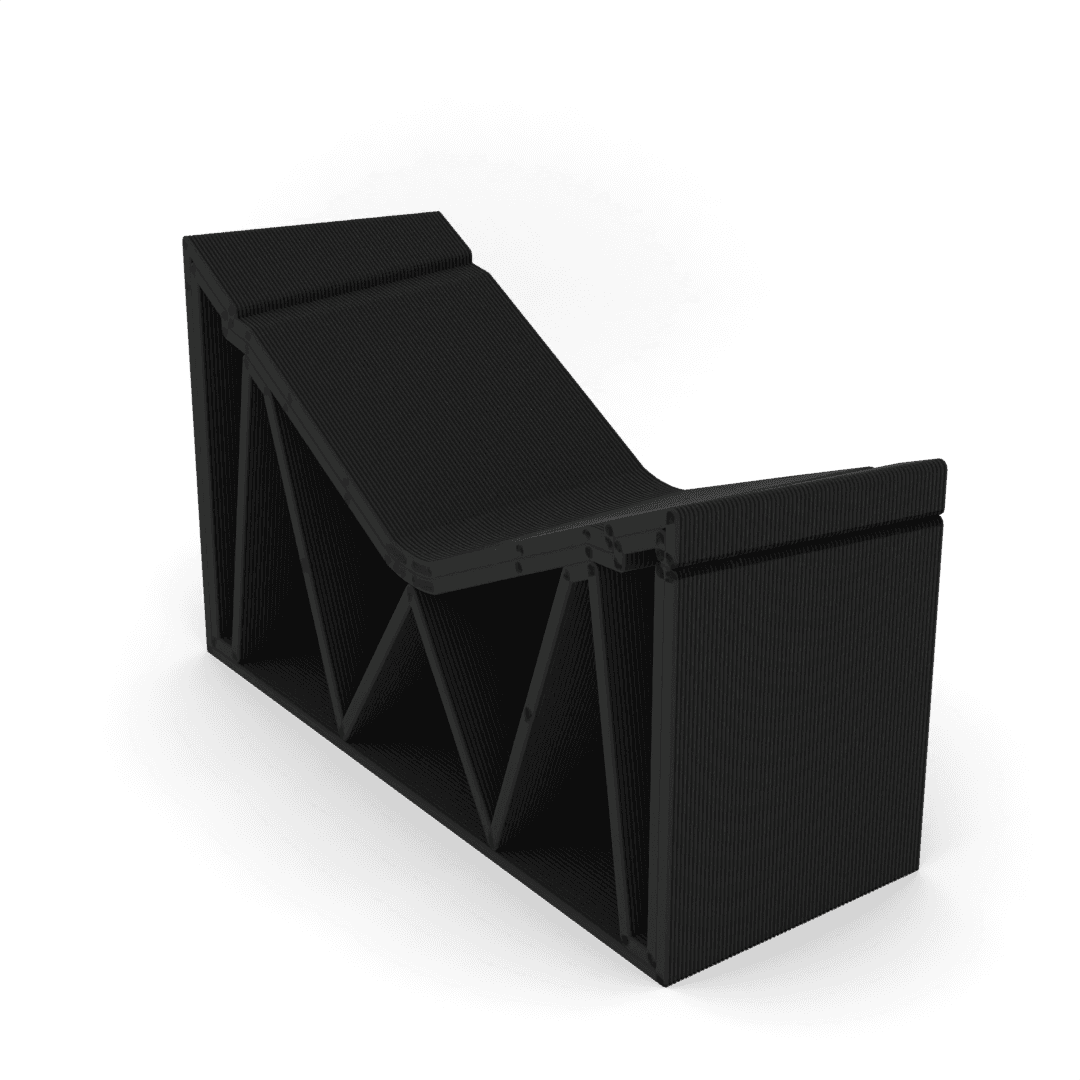

RAPID PROTOTYPES

STRUCTURAL END PARTS

STRUCTURAL SUPPORTS

SPECIALISED JIGS & TOOLING

RAPID PROTOTYPES

STRUCTURAL END PARTS

STRUCTURAL SUPPORTS

SPECIALISED JIGS & TOOLING

RAPID PROTOTYPES

STRUCTURAL END PARTS

STRUCTURAL SUPPORTS

SPECIALISED JIGS & TOOLING

RAPID PROTOTYPES

STRUCTURAL END PARTS

STRUCTURAL SUPPORTS

SPECIALISED JIGS & TOOLING

|

Our Process

01

Scope & Requirements

Our team discusses your project’s designs and requirements with you. Modifications to your design are made to optimise it for the 3D printing process. A material is selected based on your requirements. Post-processing steps are mapped out.

Design & Simulation

Your project's time, weight and resolution are estimated in more detail at this stage. The print is simulated from start to finish using Hyperion's digital twin software. The project is uploaded to our machine and manufactured as a layered 3D shape.

02

03

Manufacturing

Your project is swiftly 3D printed on our machines. Any required post-processing steps are carried out prior to finishing for delivery. Post-processing steps include milling, sanding, filling, or painting.

Blog

The Wending

Case Study

Perth, Western Australia

2/11/2024

Whats Best for Your Application? A Robotic Arm or Gantry-Based Large Format 3D Printing Solution?

Use Case

Perth, Western Australia

10/04/2024

Exploring the Benefits of Fused Granulate Fabrication

Blog

Perth, Western Australia

7/01/2024

How is 3D Printed Formwork Changing the Face of Modern Construction?

Case Study

Perth, Western Australia

30/04/2024

Hyperion and AV Landscaping's 3D Printed Plant Pots

Case Study

Perth, Western Australia

17/08/2024

Setting Sail: The Southern Hemispheres First 3D-Printed Boat

Case Study

Perth, Western Australia

16/02/2024

The Wending

Case Study

Perth, Western Australia

2/11/2024

Whats Best for Your Application? A Robotic Arm or Gantry-Based Large Format 3D Printing Solution?

Use Case

Perth, Western Australia

10/04/2024

Exploring the Benefits of Fused Granulate Fabrication

Blog

Perth, Western Australia

7/01/2024

How is 3D Printed Formwork Changing the Face of Modern Construction?

Case Study

Perth, Western Australia

30/04/2024

Hyperion and AV Landscaping's 3D Printed Plant Pots

Case Study

Perth, Western Australia

17/08/2024

Setting Sail: The Southern Hemispheres First 3D-Printed Boat

Case Study

Perth, Western Australia

16/02/2024

The Wending

Case Study

Perth, Western Australia

2/11/2024

Whats Best for Your Application? A Robotic Arm or Gantry-Based Large Format 3D Printing Solution?

Use Case

Perth, Western Australia

10/04/2024

Exploring the Benefits of Fused Granulate Fabrication

Blog

Perth, Western Australia

7/01/2024

How is 3D Printed Formwork Changing the Face of Modern Construction?

Case Study

Perth, Western Australia

30/04/2024

Hyperion and AV Landscaping's 3D Printed Plant Pots

Case Study

Perth, Western Australia

17/08/2024

Setting Sail: The Southern Hemispheres First 3D-Printed Boat

Case Study

Perth, Western Australia

16/02/2024

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

FAQ

What category of manufacturing does 3D printing belong to?

What category of manufacturing does 3D printing belong to?

What category of manufacturing does 3D printing belong to?

Are additive manufacturing and 3D printing the same, or do they differ?

Are additive manufacturing and 3D printing the same, or do they differ?

Are additive manufacturing and 3D printing the same, or do they differ?

How does additive manufacturing differ from traditional manufacturing methods?

How does additive manufacturing differ from traditional manufacturing methods?

How does additive manufacturing differ from traditional manufacturing methods?

What are the main benefits of additive manufacturing?

What are the main benefits of additive manufacturing?

What are the main benefits of additive manufacturing?

Why choose LFAM solutions to produce parts?

Why choose LFAM solutions to produce parts?

Why choose LFAM solutions to produce parts?

How do I decide which material is most suitable to print with?

How do I decide which material is most suitable to print with?

How do I decide which material is most suitable to print with?

Who will own the copyright to the printed object or material?

Who will own the copyright to the printed object or material?

Who will own the copyright to the printed object or material?

|

Why Additive Manufacturing for Defence?

In a sector where reliability and adaptability are paramount, innovation drives progress. With advanced manufacturing solutions, we enable the creation of durable, lightweight, and customized components designed to meet the evolving demands of modern defence.

|

Why Additive Manufacturing for Defence?

In a sector where reliability and adaptability are paramount, innovation drives progress. With advanced manufacturing solutions, we enable the creation of durable, lightweight, and customized components designed to meet the evolving demands of modern defence.

Rapid Deployment

Accelerate production and deployment timelines to meet urgent operational needs.

Material Innovation

Support advanced studies with precision-built prototypes.

Versatile Manufacturing

Customize approaches for precise scholarly and organizational requirements.

Complex Customisation

Foster eco-conscious learning with reduced material waste.

Supply Chain Efficiency

Minimise logistical hurdles with streamlined, localized production.

Rapid Deployment

Accelerate production and deployment timelines to meet urgent operational needs.

Material Innovation

Support advanced studies with precision-built prototypes.

Versatile Manufacturing

Customize approaches for precise scholarly and organizational requirements.

Complex Customisation

Foster eco-conscious learning with reduced material waste.

Supply Chain Efficiency

Minimise logistical hurdles with streamlined, localized production.

|

Our Process

01

Scope & Requirements

Our team discusses your project’s designs and requirements with you. Modifications to your design are made to optimise it for the 3D printing process. A material is selected based on your requirements. Post-processing steps are mapped out.

Design & Simulation

Your project's time, weight and resolution are estimated in more detail at this stage. The print is simulated from start to finish using Hyperion's digital twin software. The project is uploaded to our machine and manufactured as a layered 3D shape.

02

03

Manufacturing

Your project is swiftly 3D printed on our machines. Any required post-processing steps are carried out prior to finishing for delivery. Post-processing steps include milling, sanding, filling, or painting.

01

Scope & Requirements

Our team discusses your project’s designs and requirements with you. Modifications to your design are made to optimise it for the 3D printing process. A material is selected based on your requirements. Post-processing steps are mapped out.

Design & Simulation

Your project's time, weight and resolution are estimated in more detail at this stage. The print is simulated from start to finish using Hyperion's digital twin software. The project is uploaded to our machine and manufactured as a layered 3D shape.

02

03

Manufacturing

Your project is swiftly 3D printed on our machines. Any required post-processing steps are carried out prior to finishing for delivery. Post-processing steps include milling, sanding, filling, or painting.