LFAM for

Construction

|

Why Additive Manufcaturing for Architecture & Construction?

Modern projects require a blend of creativity, efficiency, and sustainability. Our advanced solutions empower architects and builders to craft intricate, bespoke designs with durability and speed, reimagining what’s achievable in construction.

Limitless Creativity

Unlock complex designs with precision and flexibility.

Accelerated Timelines

Complete projects faster with rapid fabrication.

Optimised Materials

Reduce waste while achieving superior strength and efficiency.

Adaptable Solutions

Scale effortlessly from small prototypes to large builds.

Eco-Friendly Practice

Build sustainably with reduced carbon footprints.

|

Construction Applications

COMMERCIAL AND RETAIL INSTALLATIONS

FORMWORKS

CUSTOM ARCHITECTURAL PROJECTS

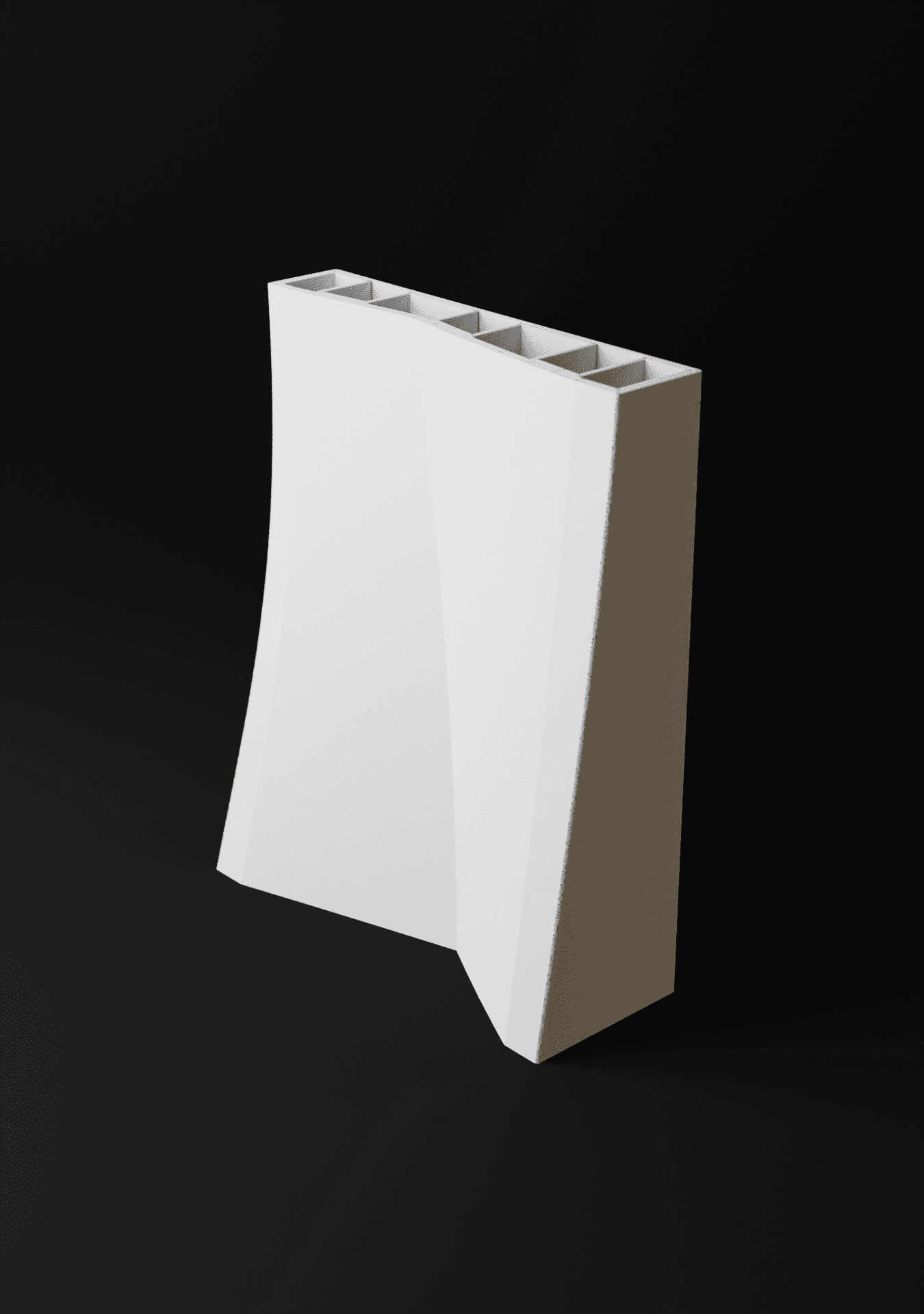

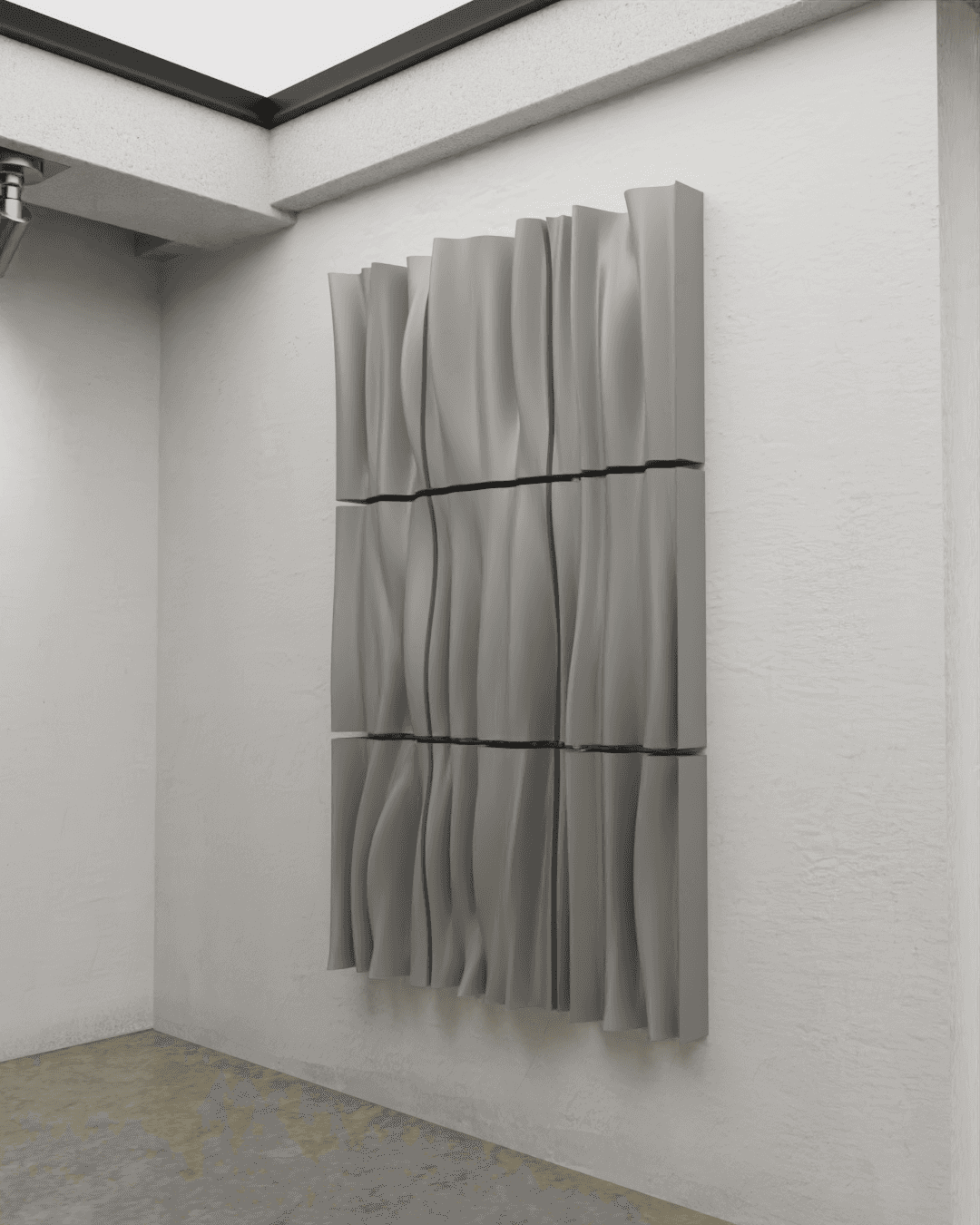

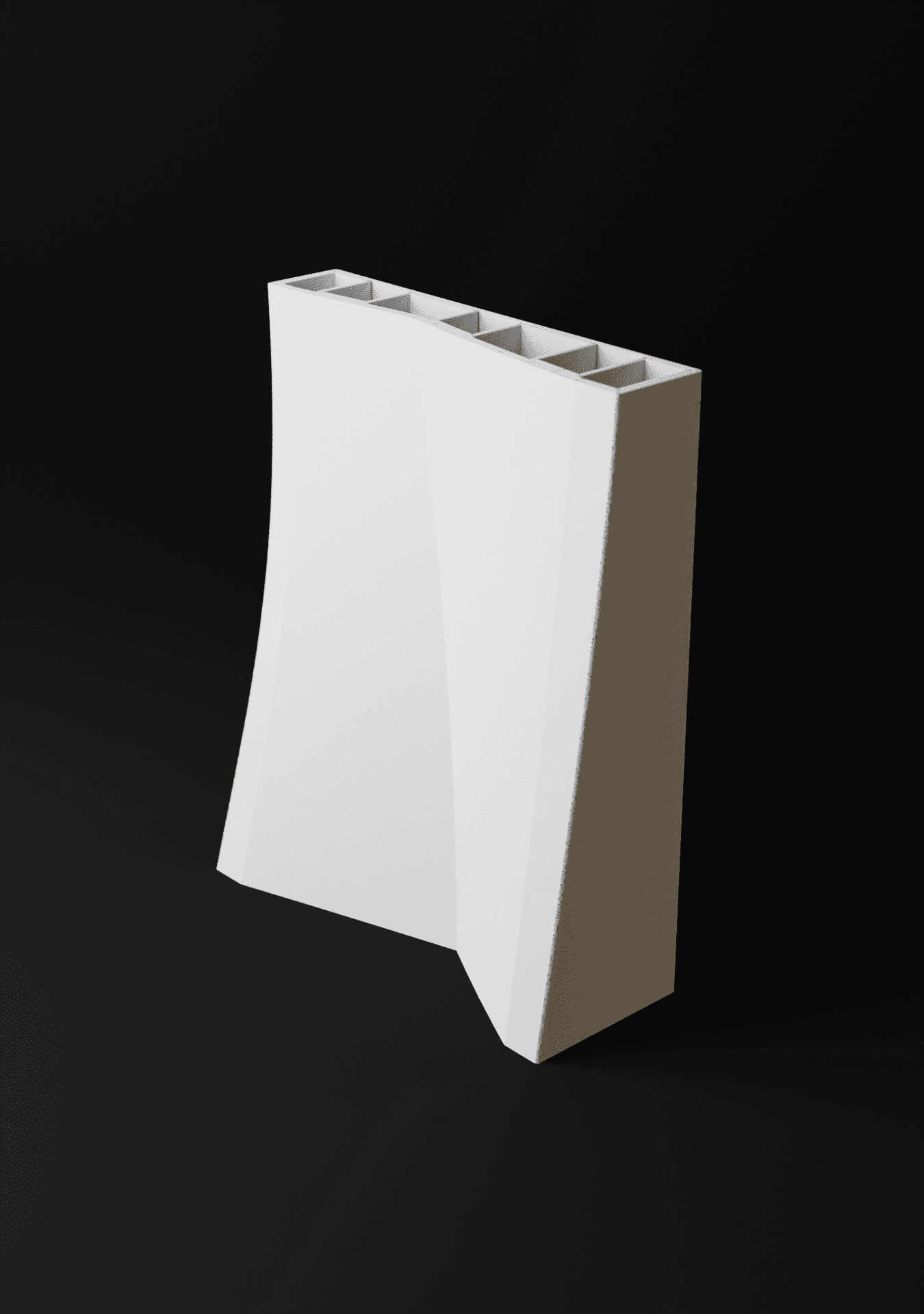

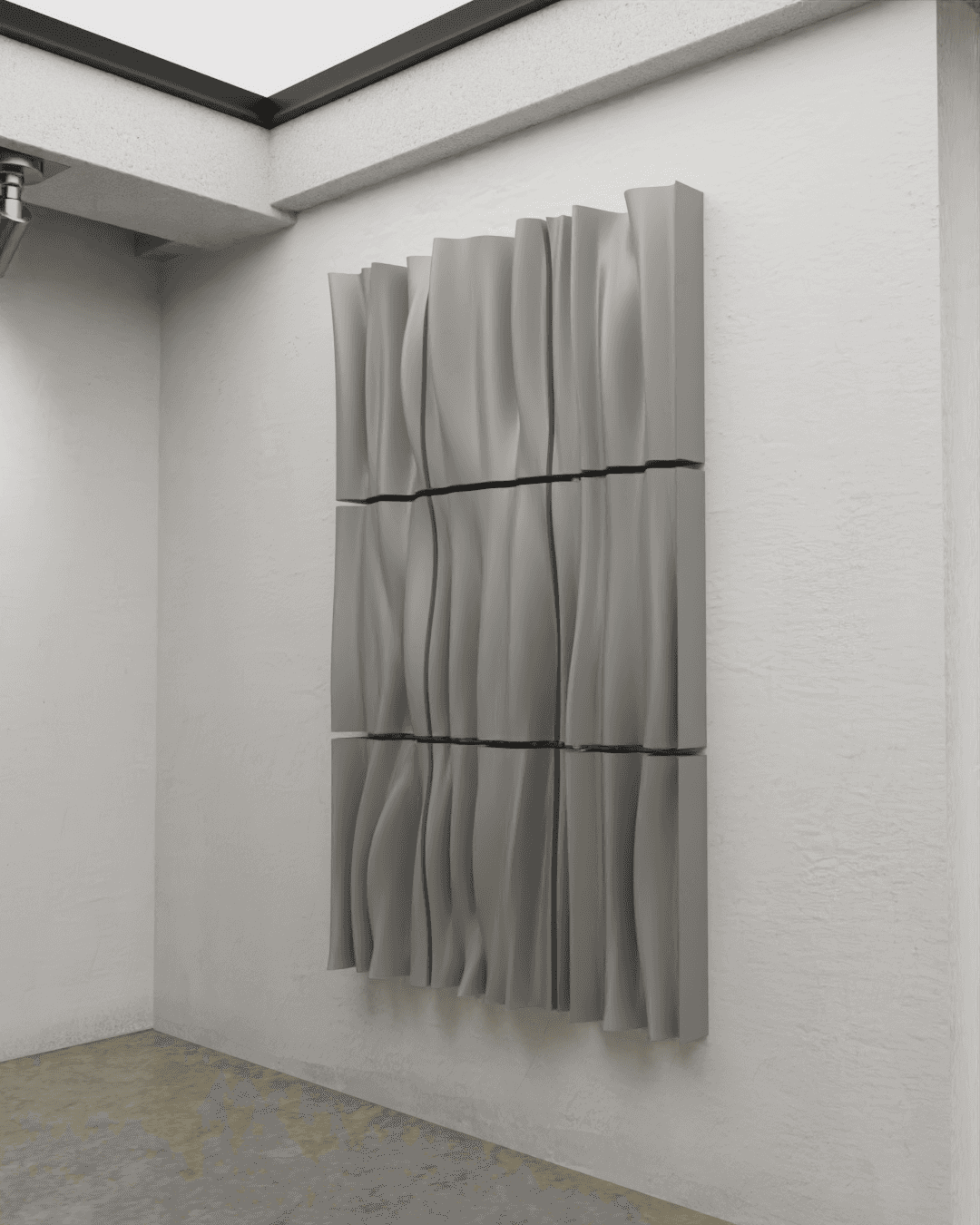

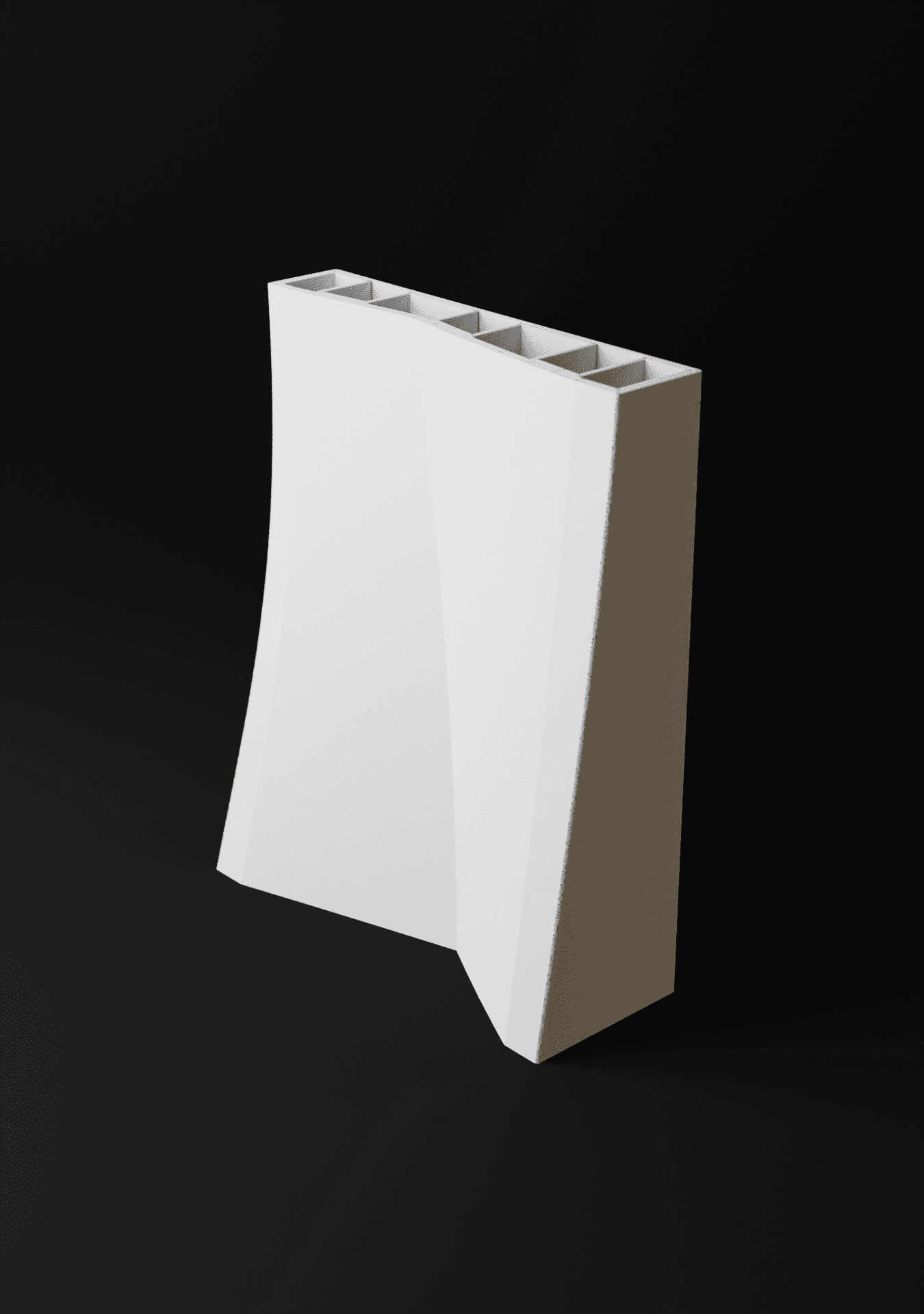

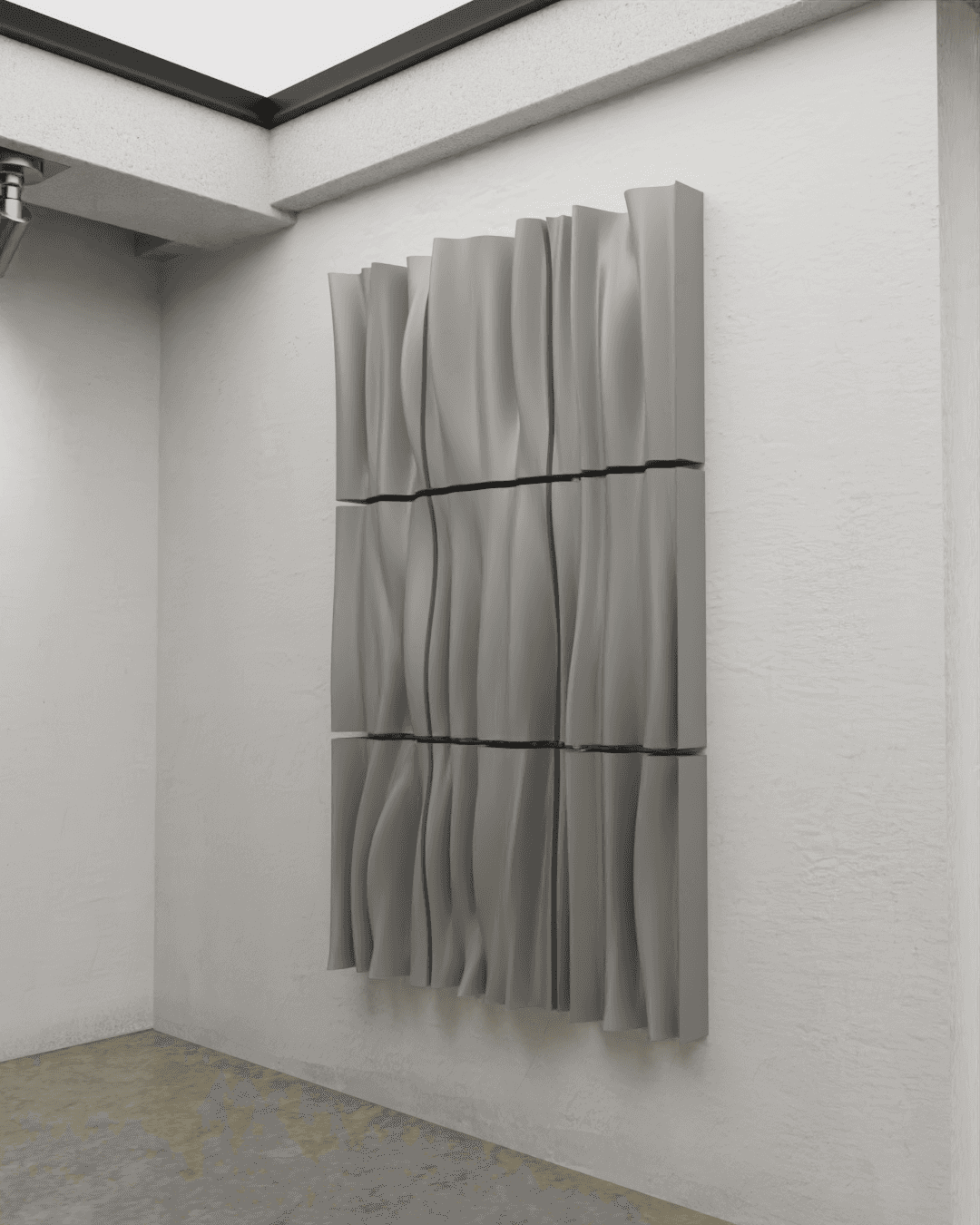

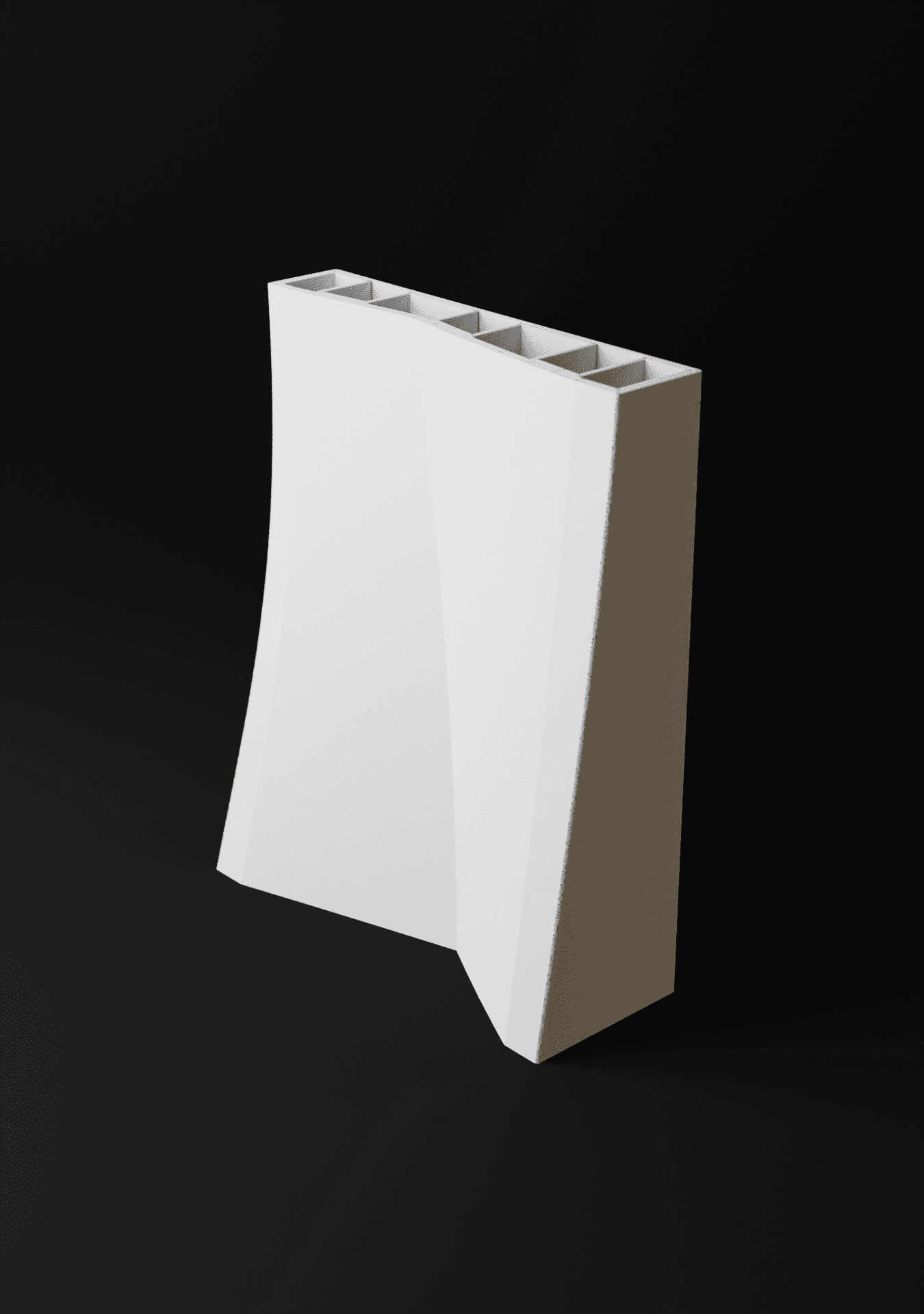

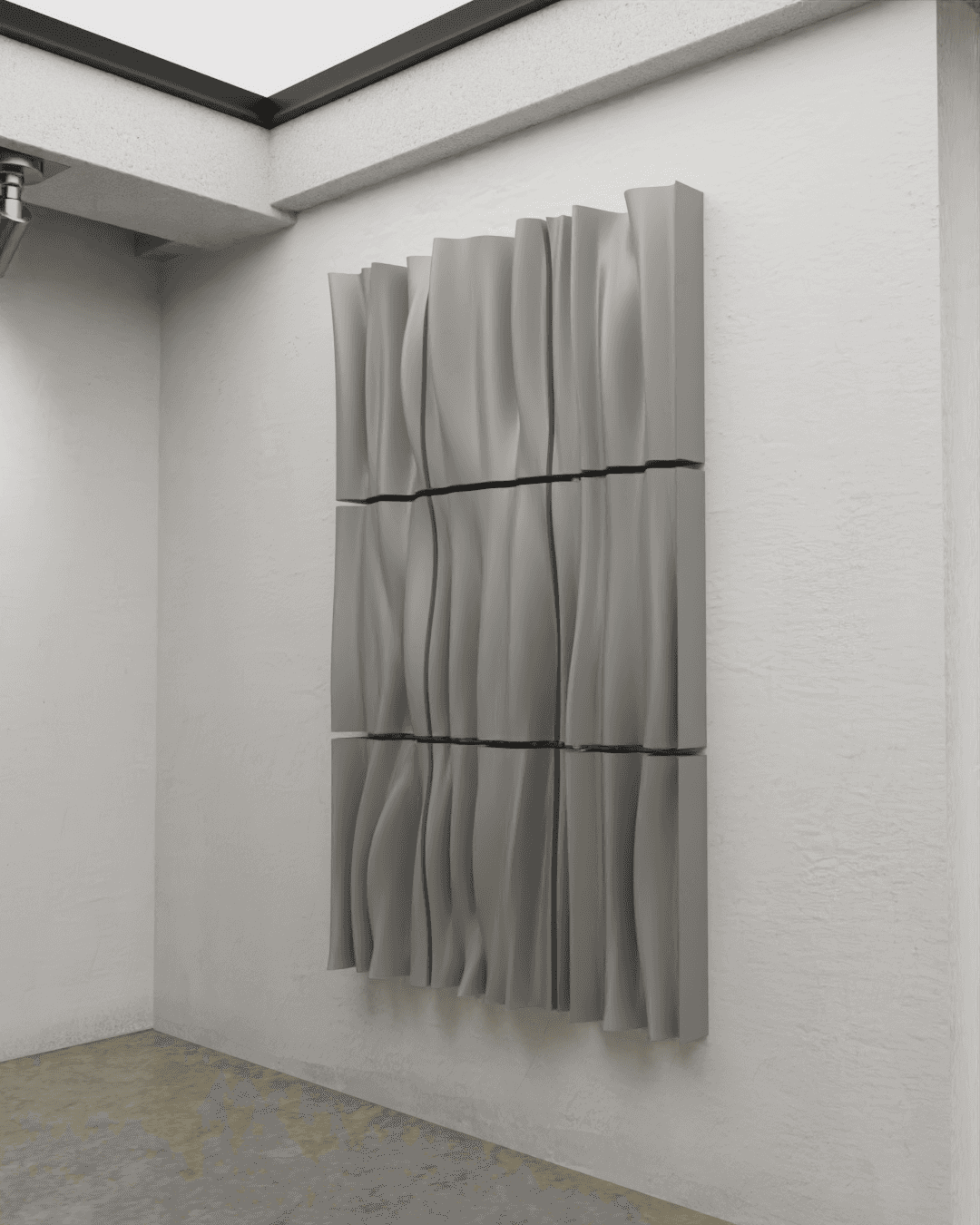

FACADES AND WALL PANELS

COMMERCIAL AND RETAIL INSTALLATIONS

FORMWORKS

CUSTOM ARCHITECTURAL PROJECTS

FACADES AND WALL PANELS

COMMERCIAL AND RETAIL INSTALLATIONS

FORMWORKS

CUSTOM ARCHITECTURAL PROJECTS

FACADES AND WALL PANELS

COMMERCIAL AND RETAIL INSTALLATIONS

FORMWORKS

CUSTOM ARCHITECTURAL PROJECTS

FACADES AND WALL PANELS

|

Our Process

01

Scope & Requirements

Our team discusses your project’s designs and requirements with you. Modifications to your design are made to optimise it for the 3D printing process. A material is selected based on your requirements. Post-processing steps are mapped out.

Design & Simulation

Your project's time, weight and resolution are estimated in more detail at this stage. The print is simulated from start to finish using Hyperion's digital twin software. The project is uploaded to our machine and manufactured as a layered 3D shape.

02

03

Manufacturing

Your project is swiftly 3D printed on our machines. Any required post-processing steps are carried out prior to finishing for delivery. Post-processing steps include milling, sanding, filling, or painting.

BLOG

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

FAQ

What category of manufacturing does 3D printing belong to?

What category of manufacturing does 3D printing belong to?

What category of manufacturing does 3D printing belong to?

Are additive manufacturing and 3D printing the same, or do they differ?

Are additive manufacturing and 3D printing the same, or do they differ?

Are additive manufacturing and 3D printing the same, or do they differ?

How does additive manufacturing differ from traditional manufacturing methods?

How does additive manufacturing differ from traditional manufacturing methods?

How does additive manufacturing differ from traditional manufacturing methods?

What are the main benefits of additive manufacturing?

What are the main benefits of additive manufacturing?

What are the main benefits of additive manufacturing?

Why choose LFAM solutions to produce parts?

Why choose LFAM solutions to produce parts?

Why choose LFAM solutions to produce parts?

How do I decide which material is most suitable to print with?

How do I decide which material is most suitable to print with?

How do I decide which material is most suitable to print with?

Who will own the copyright to the printed object or material?

Who will own the copyright to the printed object or material?

Who will own the copyright to the printed object or material?

|

Our Process

01

01

Scope & Requirements

Our team discusses your project’s designs and requirements with you. Modifications to your design are made to optimise it for the 3D printing process. A material is selected based on your requirements. Post-processing steps are mapped out.

Design & Simulation

Your project's time, weight and resolution are estimated in more detail at this stage. The print is simulated from start to finish using Hyperion's digital twin software. The project is uploaded to our machine and manufactured as a layered 3D shape.

02

02

03

03

Manufacturing

Your project is swiftly 3D printed on our machines. Any required post-processing steps are carried out prior to finishing for delivery. Post-processing steps include milling, sanding, filling, or painting.

|

Why Additive Manufacturing for Construction?

|

Why Additive Manufacturing for Construction?

Modern projects require a blend of creativity, efficiency, and sustainability. Our advanced solutions empower architects and builders to craft intricate, bespoke designs with durability and speed, reimagining what’s achievable in construction.

Limitless Creativity

Unlock complex designs with precision and flexibility.

Accelerated Timelines

Complete projects faster with rapid fabrication.

Optimised Materials

Reduce waste while achieving superior strength and efficiency.

Eco-Friendly Practice

Build sustainably with reduced carbon footprints.

Adaptable Solutions

Scale effortlessly from small prototypes to large builds.

Limitless Creativity

Unlock complex designs with precision and flexibility.

Accelerated Timelines

Complete projects faster with rapid fabrication.

Optimised Materials

Reduce waste while achieving superior strength and efficiency.

Adaptable Solutions

Scale effortlessly from small prototypes to large builds.

Eco-Friendly Practice

Build sustainably with reduced carbon footprints.

|

Our Process

01

Scope & Requirements

Our team discusses your project’s designs and requirements with you. Modifications to your design are made to optimise it for the 3D printing process. A material is selected based on your requirements. Post-processing steps are mapped out.

Design & Simulation

Your project's time, weight and resolution are estimated in more detail at this stage. The print is simulated from start to finish using Hyperion's digital twin software. The project is uploaded to our machine and manufactured as a layered 3D shape.

02

03

Manufacturing

Your project is swiftly 3D printed on our machines. Any required post-processing steps are carried out prior to finishing for delivery. Post-processing steps include milling, sanding, filling, or painting.