Capabilities

Hyperion is your comprehensive solution for Large-Format 3D Printing, offering expertise in manufacturing, hardware, software and material formulations. We tailor our services to meet the needs of various sectors and applications.

|

Contract Manufacturing

Hyperion's contract manufacturing services provide end-to-end solutions for bringing complex ideas to life with speed and precision.

3D Printing

Leverage large-format 3D printing for cost-efficient, scalable production of intricate parts. By reducing lead times and material waste, Hyperion accelerates the path from concept to production while maintaining a commitment to sustainability.

Concept Engineering

Deliver durable, high-performance components designed for demanding industries such as marine, defence, and architecture. Hyperion’s expertise ensures every part meets strict functional and environmental requirements.

|

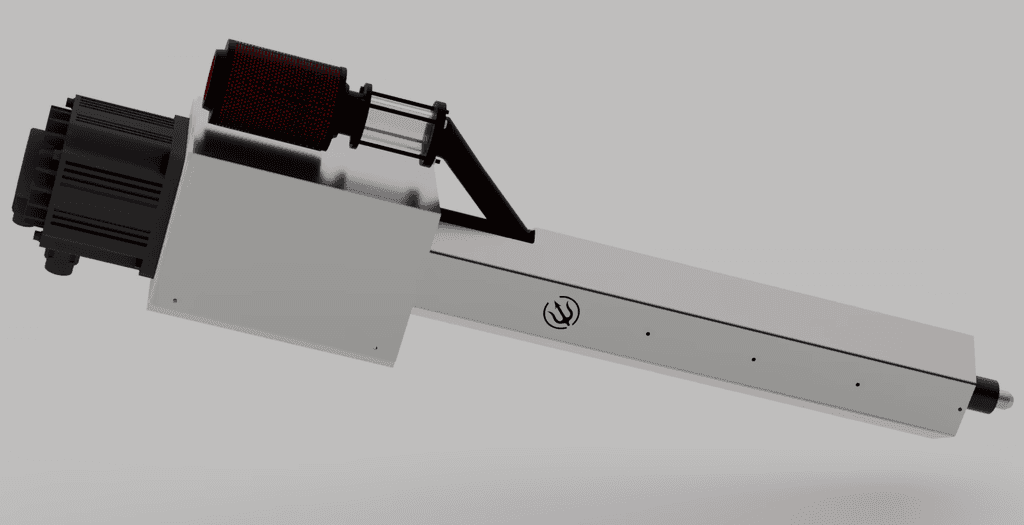

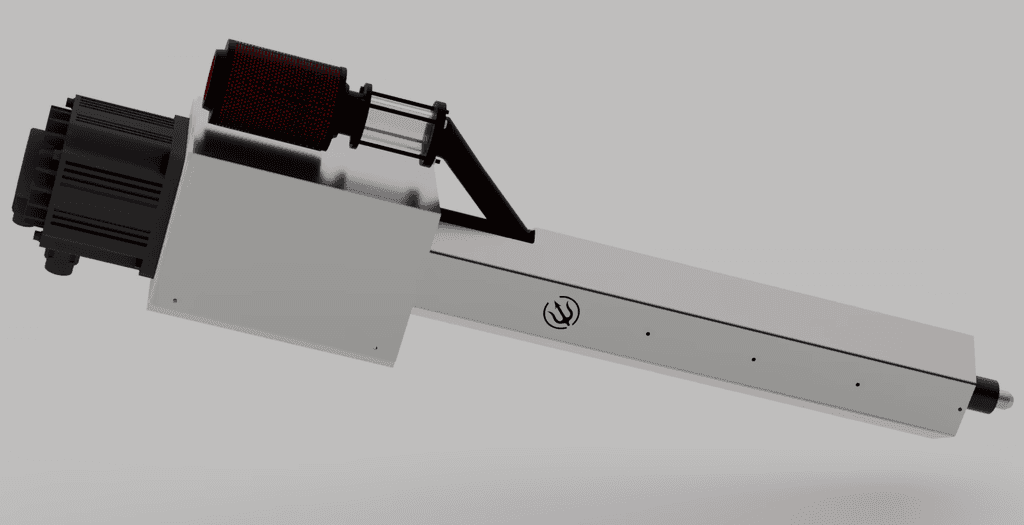

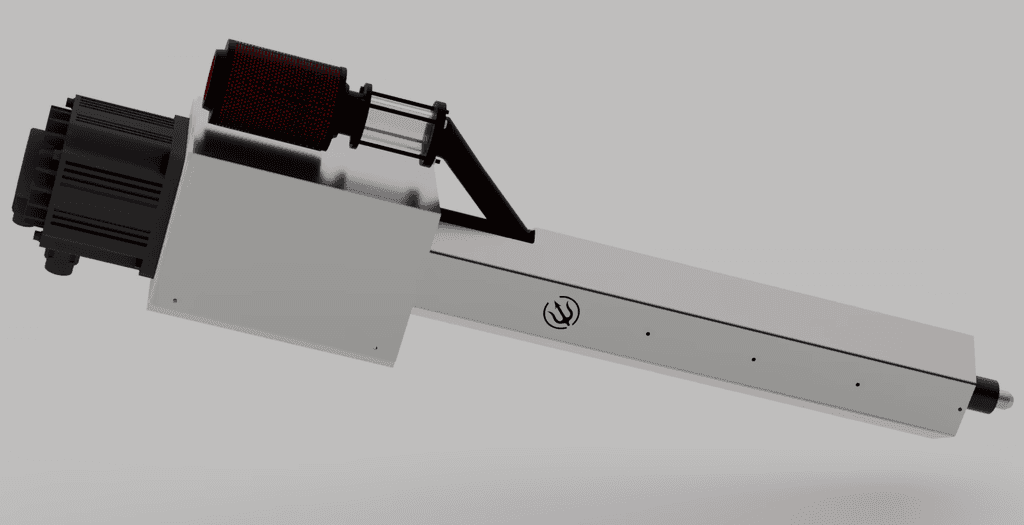

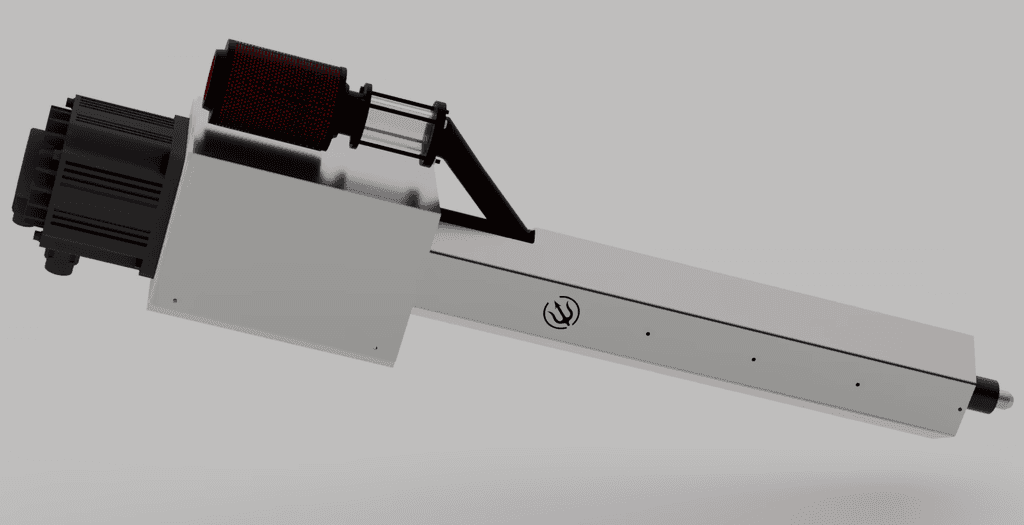

Hardware

Hyperion's hardware solutions offer robust, adaptable systems tailored for diverse industrial applications.

Machine and System Integration

Design and manufacture large-format 3D printers optimized for specific industry needs, ensuring seamless integration into existing production workflows. Each machine is built for reliability and precision to handle complex, large-scale projects.

Flexible and Expandable Upgrades

Provide hardware modularity and custom upgrades that adapt to growing production demands. Whether scaling up or integrating new materials and techniques, Hyperion’s systems evolve with your business.

|

Software

Hyperion’s software capabilities streamline and enhance production with advanced integration and multi-functional control.

Advanced Integration

Seamlessly integrate CAD/CAM software for both additive and subtractive manufacturing. This dual functionality simplifies workflows, enabling precise execution of even the most intricate designs.

More Than FDM

Beyond traditional fused deposition modeling, Hyperion’s software supports slicing for WAAM (Wire Arc Additive Manufacturing), metal printing, concrete, and other specialized materials. This flexibility ensures compatibility with a wide range of applications and industries.

|

Materials

Hyperion’s material expertise ensures access to sustainable, high-performance options tailored to specific application needs.

Advanced Integration

Source and implement advanced thermoplastics with multifunctional properties, such as high strength-to-weight ratios, thermal resistance, and recyclability. These materials support eco-friendly manufacturing without compromising performance.

More Than FDM

Utilise large-scale compounding systems to recycle and repurpose plastics. By incorporating additives and fillers, we create customised materials that enhance durability, functionality, and sustainability for industrial applications.

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

Let’s Shape the Future Together with Additive Manufacturing.

Talk to our experts about your additive manufacturing needs.

|

Contract Manufacturing

Hyperion's contract manufacturing services provide end-to-end solutions for bringing complex ideas to life with speed and precision.

3D Printing

Leverage large-format 3D printing for cost-efficient, scalable production of intricate parts. By reducing lead times and material waste, Hyperion accelerates the path from concept to production while maintaining a commitment to sustainability.

Concept Engineering

Deliver durable, high-performance components designed for demanding industries such as marine, defence, and architecture. Hyperion’s expertise ensures every part meets strict functional and environmental requirements.

|

Hardware

Hyperion's hardware solutions offer robust, adaptable systems tailored for diverse industrial applications.

Machine and System Integration

Design and manufacture large-format 3D printers optimized for specific industry needs, ensuring seamless integration into existing production workflows. Each machine is built for reliability and precision to handle complex, large-scale projects.

Flexible and Expandable Upgrades

Provide hardware modularity and custom upgrades that adapt to growing production demands. Whether scaling up or integrating new materials and techniques, Hyperion’s systems evolve with your business.

|

Materials

Hyperion’s material expertise ensures access to sustainable, high-performance options tailored to specific application needs.

Advanced Integration

Source and implement advanced thermoplastics with multifunctional properties, such as high strength-to-weight ratios, thermal resistance, and recyclability. These materials support eco-friendly manufacturing without compromising performance.

More Than FDM

Utilise large-scale compounding systems to recycle and repurpose plastics. By incorporating additives and fillers, we create customised materials that enhance durability, functionality, and sustainability for industrial applications.

|

Software

Hyperion’s software capabilities streamline and enhance production with advanced integration and multi-functional control.

Advanced Integration

Seamlessly integrate CAD/CAM software for both additive and subtractive manufacturing. This dual functionality simplifies workflows, enabling precise execution of even the most intricate designs.

More Than FDM

Beyond traditional fused deposition modeling, Hyperion’s software supports slicing for WAAM (Wire Arc Additive Manufacturing), metal printing, concrete, and other specialized materials. This flexibility ensures compatibility with a wide range of applications and industries.